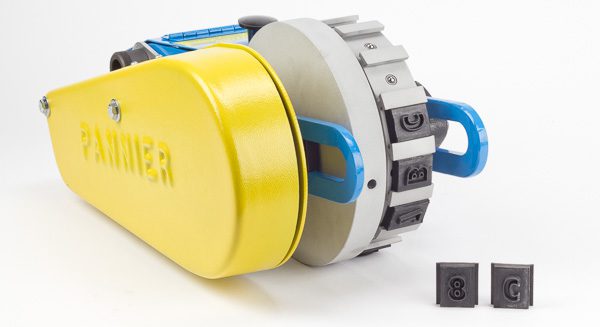

The Rubber Printing System is the first ink jet printer in the world to successfully print with co-curable inks on uncured tire components and rubber products. This specialized printer fully automates the marking process, streamlining production and eliminating marking mistakes. The RPS is used by tire and rubber manufacturers worldwide for reliable product identification.

New 2.0 RPS is here! The latest version of the Rubber Printing System features all-new components:

- 2.0 print heads have been redesigned for improved print quality and service life

- The ink supply system uses automatic print head flushing to prevent clogs

- The new TITAN controller can be monitored and managed remotely

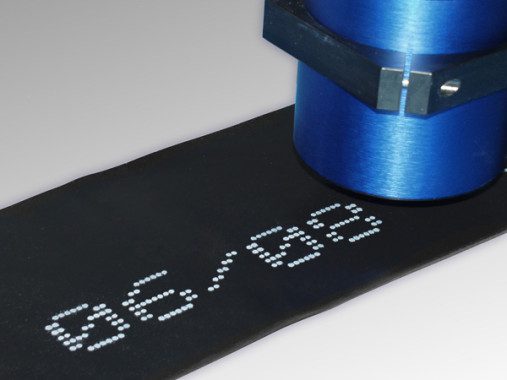

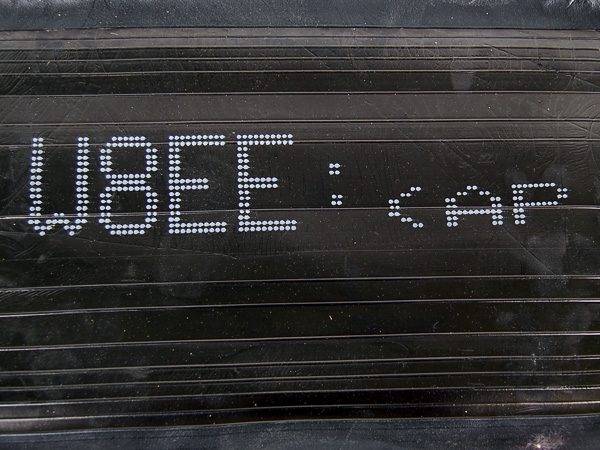

Mistake-Proof Marking of Uncured Rubber Products

- Print real-time batch, date, and time codes for precise product tracking

- Non-contact ink jet printing can be applied without affecting the surface of the product

- Co-curable inks do not affect adhesion of components and won’t transfer to molds

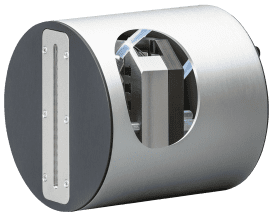

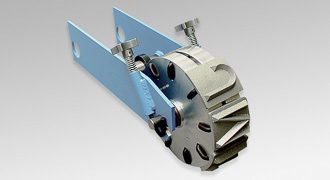

Patented Print Head Design

The printer’s patented print head and specialized ink supply make the Rubber Printing System unlike any other ink jet printer. The valve-less print heads allow the use of specialty inks which are then properly circulated to prevent clogging or settling within the printer. The result is a revolutionary advance in printing technology for marking rubber products, giving manufacturers a whole new level of product traceability.

- Internal components resist wear caused by inks with pigments and particulates

- Ink continually circulates through the head to prevent ink settling

- A purge button on the back of each head and automatic flushing from the ink supply prevent clogs

- Heads can be removed and replaced quickly when service is needed