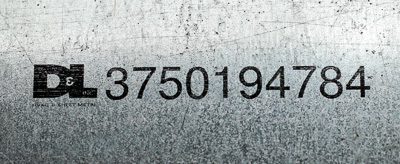

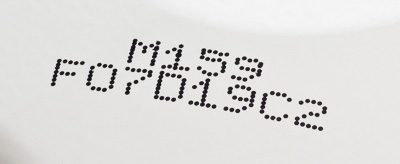

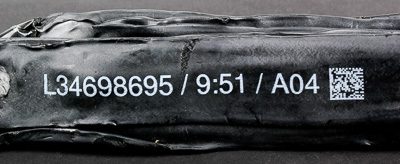

Continuous ink jet (CIJ) printers have been used for many years for consumer and industrial product coding applications. They print small character text, logos, and bar codes on a variety of products from food and beverage containers to lumber and pipe. But there are many inherent complexities and costs in using CIJ printers, many of which are explained below.

A newer way of accomplishing small character printing is with HR thermal ink jet (TIJ) printers. TIJ printers use replaceable ink jet cartridges similar to those used in desktop office printers, but they’ve been modified for use on a production line. Specialized inks are available for printing on metals, plastics, fabrics, and wood. The print resolution is better than CIJ and many of the maintenance issues associated with CIJ are eliminated.

Compare Features |

Thermal Ink Jet (TIJ) |

Continuous Ink Jet (CIJ) |

| Print Resolution |  TIJ prints in high resolution up to 600 x 600 dpi, like a desktop ink jet printer. |

CIJ prints a low-resolution dot pattern. |

|---|---|---|

| Print Speed |

Both TIJ and CIJ can be used for very fast applications. |

|

| Throw Distance | TIJ printhead must be close to the product – within a few millimeters. The product being marked must be smooth-moving (not bouncing). | The CIJ printhead can be placed farther away from the product. The code gets larger as you print from farther away. More forgiving when printing on inconsistently moving product (bouncing). |

| Cleanup | TIJ printheads create very little mess. When minor cleanup is needed, a mild, diluted, alcohol-based cleaning solution is used. | The floor beneath a CIJ printing station is typically coated with ink over time. Cleanup requires harsh solvents requiring ventilation for operator safety. |

| Recovery from Downtime | TIJ has little downtime because there are few moving parts. A new printhead is introduced with each cartridge. | When CIJ printers go down, they go down hard. Often a service technician must be called in. |

| System Modularity | TIJ systems are modular so all components can be swapped out individually if necessary. There is no expensive umbilical – just a printhead cable that quickly disconnects. | CIJ printers are closed-loop systems. When something goes wrong, the entire printer must be removed for service. Components are thus difficult and expensive to repair or replace – the “umbilical” is the best example and can cost $1,000’s to replace. |

| Service Contract | TIJ printers would never warrant a service contract. There are few moving parts and the cartridges are disposable. | CIJ printers usually require a monthly service contract because of expected downtime and the complexity of the system. |

Ink Performance |

Thermal Ink Jet (TIJ) |

Continuous Ink Jet (CIJ) |

| Ink Drying Time | TIJ has specialized inks with fast dry time. | CIJ has a wide variety of inks for industrial applications with fast dry time. |

|---|---|---|

| Porous Surfaces | TIJ is the best choice for printing on porous surfaces such as paper, cardboard, wood, and fabric. Dry time is very good even with mild inks. These applications lend themselves to bolder text, higher resolution, and sometimes bar codes. | The harsh solvents used in CIJ printing inks are unnecessary for porous applications. |

| Non-porous Surfaces | TIJ marks can be permanent enough on non-porous surfaces, but are easier to remove in general and with solvents. TIJ does best printing on a clean surface; if there is a layer of oil the mark will likely wipe off. | CIJ uses harsh solvents and it can achieve better adhesion and permanence on non-porous surfaces. CIJ has the adhesion advantage, especially when printing on oily surfaces. |

| Black Ink |

Both TIJ and CIJ are ideally suited for use with black ink. |

|

| White Ink |  White ink cartridges are available for TIJ, but they are sensitive. For example, they must be stored upside-down, shaken periodically during use, and capped immediately when printing is finished. Once a white ink jet cartridge becomes clogged it is typically unrecoverable. |

CIJ printers are available for printing white ink. When used continuously (such as printing date codes on bottles) they can run well. When used intermittently they have terrible recovery from downtime and often require a service visit. |

| Make-up Fluid | TIJ printers do not use make-up fluid. | CIJ printers continuously consume make-up fluid. |