The smallest marking laser in the world, the NanoVIS is a revolutionary laser that yields results comparable to more expensive units in a compact unit weighing less than 17 lbs. Using the patent pending a-Wave® technology, the nanoVIS marks most metals, plastics, ceramics, and more with automatic regulation of frequency up to 20W. Get marking results similar to systems that cost 2 to 3 times more.

The nanoVIS software is easy to learn, multilingual, and gives the user many parameters to adjust for ultimate marking performance.

- mark text, logos and graphics, bar codes, and 2D codes

- automatically mark serial numbers, shift codes, and date codes

- mark any TrueType font (TTF)

- import and mark DXF, JPG, BMP and GIF graphics

| Laser Type | a-Wave® with auto regulation, 1060 nm wavelength |

|---|---|

| Laser Power | 6 W, variable |

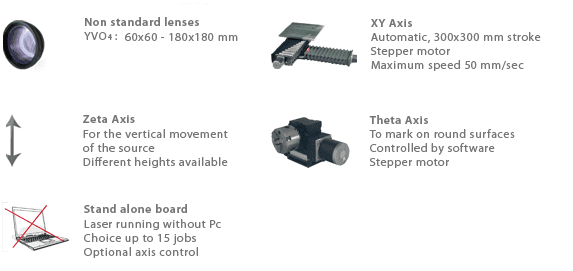

| Lens Options | F100 Lens – 60 x 60 mm marking area (2.3″ x 2.3″)

F160 Lens – 110 x 110 mm marking area (4.3″ x 4.3″) |

| Safety Classification | Class 4 |

| Dimensions L x W x H | 327.7 x 165 x 202.6 mm | 12.9″ x 6.5″ x 8.0″ |

| Weight | 7.7 kg | 16.9 lb |

| Power Supply | 100V / 240V 24VDC |

| Graphics File Types Accepted | DXF, JPG, BMP and GIF |