Pannier offers a wide variety of laser marking systems for the automotive, aerospace, oil and gas, and other manufacturing industries. Our range of solutions allow us to meet our customers’ needs for engraving, etching, annealing, or ablation on nearly any product surface for permanent part identification. Whether you are looking for a laser to integrate into your production line or use as a stand-alone part marking workstation, we have your solution.

Lasers can be incorporated into Class 1 safety enclosures which completely enclose the laser beam. Each workstation features safety interlocks to prevent the laser from operating when the door is open, and laser-safe glass allows the operator to view the marking process.

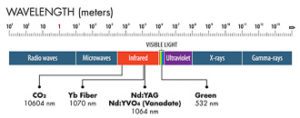

Different lasers can be used for marking different materials. Pannier’s range of powerful and versatile lasers feature dual-galvanometer beam movement for fast, high-resolution marking of text, QR codes, and logos. Mark metal and plastic items in just seconds. Class 1 workstations are available in different sizes to accommodate the size and shape of the items being marked.

Custom enclosures can be also designed to meet your specific needs.

Typical Marking and Coding Applications

- laser engraving metal parts

- filling in information on serial plates and asset tags

- marking around the circumference of round parts

- marking trays of parts

Laser systems are the ideal choice when permanent, high-quality marks are required on parts during production. Laser marking is fast and maintenance-free, making it an attractive alternative to ink jet marking, chemical etching, or labels. Pannier offers a wide range of Class 4 OEM lasers for integration into production lines and automation cells.

Typical Marking and Coding Applications

- automotive parts made of metal, plastic, or rubber

- extruded plastic products

- packaging and consumer goods

Max Marking Area: 320 x 320 mm

![]()

Max Marking Area: 324 x 324 mm

Max Marking Area: 324 x 324 mm

Max Marking Area: 324 x 324 mm

Max Marking Area: 300 x 300 mm

Max Marking Area: 250 x 250 mm