Membrane roofing material is commonly printed with lines to indicate where the material should be…

Identifying product defects on a continuous production line is an essential element of quality control for today’s manufacturers. If defective sections of products can be identified and removed from production runs, product failures can be reduced and customer satisfaction is improved.

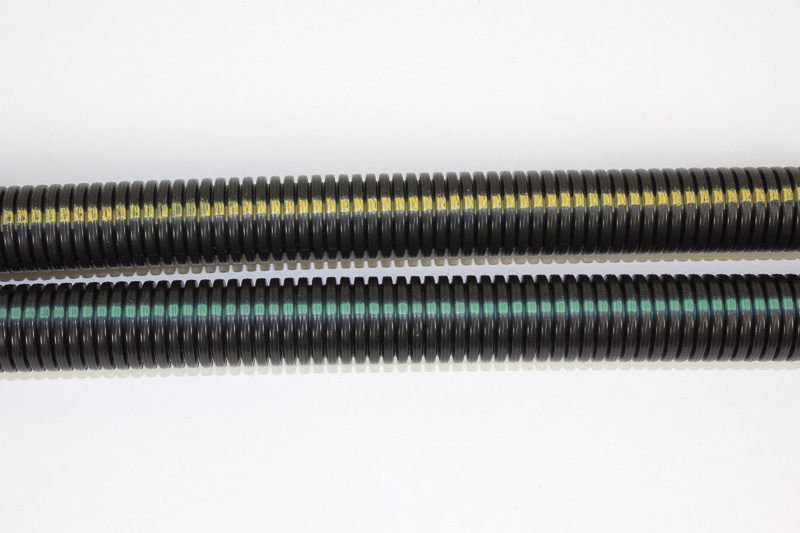

A manufacturer of corrugated plastic tubing for automotive and industrial fluid handling needed to improve the defect identification system in their manufacturing operations. The hose is either black or white and they were looking for a printing system that could immediately apply brightly colored stripes to the tube as soon as defects were detected. The stripes would allow for easy visual identification so defective sections could be cut from the rolls of material prior to shipping.

They had previously tried using a CIJ ink jet printer to make the stripes, but the marks were too faint and the system’s print head required too much maintenance since it was only used intermittently. The CIJ printer also could only work with MEK-based ink, a hazardous fluid that many manufacturers seek to eliminate from production environments.

They contacted Pannier to discuss the ST spray marking systems for applying large, dense stripes using spray heads. Spray systems require less maintenance and are simple to actuate. Pannier tested various inks on the hose in their lab and determined that less hazardous ethanol-based inks worked well. Pannier was able to deliver five complete systems with necessary brackets, tubing, and ink supply components for easy installation on all of the customer’s production lines.